About Photovoltaic silicon panel production

Solar manufacturing encompasses the production of products and materials across the solar value chain. This page provides background information on several manufacturing processes to help you better understand how solar works.

Silicon PV Most commercially available PV modules rely on crystalline silicon as the absorber material. These modules have several manufacturing.

The support structures that are built to support PV modules on a roof or in a field are commonly referred to as racking systems. The manufacture.

Power electronics for PV modules, including power optimizers and inverters, are assembled on electronic circuit boards. This hardware converts direct current (DC) electricity.

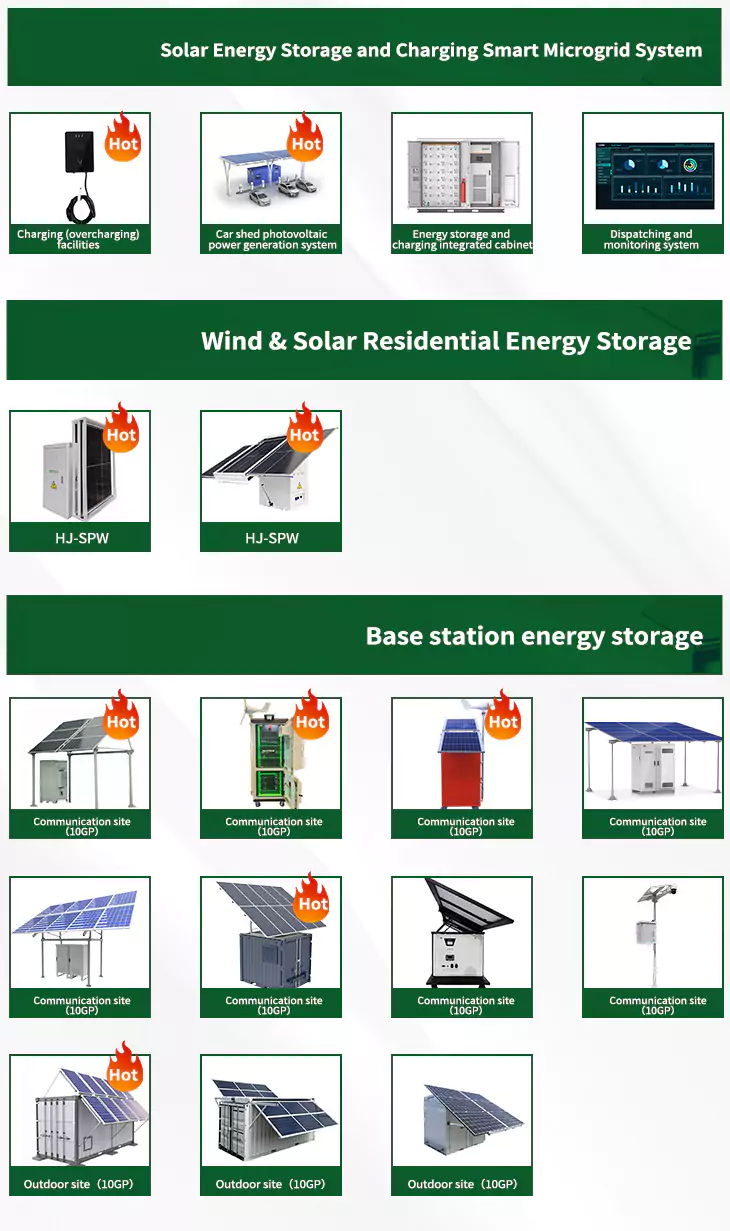

As the photovoltaic (PV) industry continues to evolve, advancements in Photovoltaic silicon panel production have become critical to optimizing the utilization of renewable energy sources. From innovative battery technologies to intelligent energy management systems, these solutions are transforming the way we store and distribute solar-generated electricity.

When you're looking for the latest and most efficient Photovoltaic silicon panel production for your PV project, our website offers a comprehensive selection of cutting-edge products designed to meet your specific requirements. Whether you're a renewable energy developer, utility company, or commercial enterprise looking to reduce your carbon footprint, we have the solutions to help you harness the full potential of solar energy.

By interacting with our online customer service, you'll gain a deep understanding of the various Photovoltaic silicon panel production featured in our extensive catalog, such as high-efficiency storage batteries and intelligent energy management systems, and how they work together to provide a stable and reliable power supply for your PV projects.

6 FAQs about [Photovoltaic silicon panel production]

Can thin-film silicon photovoltaics be used for solar energy?

The ability to engineer efficient silicon solar cells using a-Si:H layers was demonstrated in the early 1990s 113, 114. Many research laboratories with expertise in thin-film silicon photovoltaics joined the effort in the past 15 years, following the decline of this technology for large-scale energy production.

Why is the supply chain for crystalline silicon (c-Si) photovoltaic panels so fragile?

Nature Communications 14, Article number: 1274 (2023) Cite this article The gloChinazed supply chain for crystalline silicon (c-Si) photovoltaic (PV) panels is increasingly fragile, as the now-mundane freight crisis and other geopolitical risks threaten to postpone major PV projects.

Is polysilicon a bottleneck for solar PV?

Global capacity for manufacturing wafers and cells, which are key solar PV elements, and for assembling them into solar panels (also known as modules), exceeded demand by at least 100% at the end of 2021. By contrast, production of polysilicon, the key material for solar PV, is currently a bottleneck in an otherwise oversupplied supply chain.

Why is monocrystalline silicon used in photovoltaic cells?

In the field of solar energy, monocrystalline silicon is also used to make photovoltaic cells due to its ability to absorb radiation. Monocrystalline silicon consists of silicon in which the crystal lattice of the entire solid is continuous. This crystalline structure does not break at its edges and is free of any grain boundaries.

Does thin-film silicon photovoltaics have a synergy?

Many research laboratories with expertise in thin-film silicon photovoltaics joined the effort in the past 15 years, following the decline of this technology for large-scale energy production. Their success suggests that strong synergies exist between the two fields 57, 79, 115, 116, 117, 118.

Why is reshoring silicon photovoltaic manufacturing back to the United States?

Reshoring silicon photovoltaic manufacturing back to the U.S. improves domestic competitiveness, advances decarbonization goals, and contributes to mitigating climate change.

Related Contents

- Photovoltaic panel 3D production line

- Photosynthetic silicon energy flexible photovoltaic panel

- Photovoltaic panel electroplating production process

- How much does a photovoltaic panel production plant cost

- Photovoltaic panel production standards

- Solar photovoltaic panel production site

- Flexible photovoltaic panel production

- Tongwei photovoltaic panel production process diagram

- How much does a photovoltaic silicon panel polishing machine cost

- Photovoltaic panel production process engineer

- Monocrystalline silicon photovoltaic panel efficiency

- Small-scale photovoltaic panel machine production