About Are photovoltaic panels nickel-plated

Abstract. Electroplating copper technology offers advantages such as low cost, good conductivity, and a simple process, making it a promising solution in the photovoltaics (PV) field. However, despite its effectiveness in reducing silver consumption, a significant challenge arises from suboptimal electrical contact between metal electrodes and .

Abstract. Electroplating copper technology offers advantages such as low cost, good conductivity, and a simple process, making it a promising solution in the photovoltaics (PV) field. However, despite its effectiveness in reducing silver consumption, a significant challenge arises from suboptimal electrical contact between metal electrodes and .

This chapter deals with issues regarding contact formations using Ni/Cu metal stacks for crystalline silicon solar cells. The key issues for the discussed technology are: (i) an effective Ni seed layer formation, and (ii) the development of Cu metal contacts by the LIP process.

This study reports on the application of a contact stack consisting of Ag, nickel (Ni), and copper (Cu) in Si solar cells. To prevent Schottky contact formation, Ag is implemented as a seed layer, whereas Ni and Cu form the metal bulk layer.

The standard processing sequence of Ni/Cu contact formation involves two steps: in the first step, (i) Ni metal film is plated on to the solar cell surface, followed by (ii) the final step of plating a copper metal film on top of the Ni.

Metal contacts are fabricated by nickel (Ni) electroplating directly onto the solar cell’s front using a precisely structured mask.

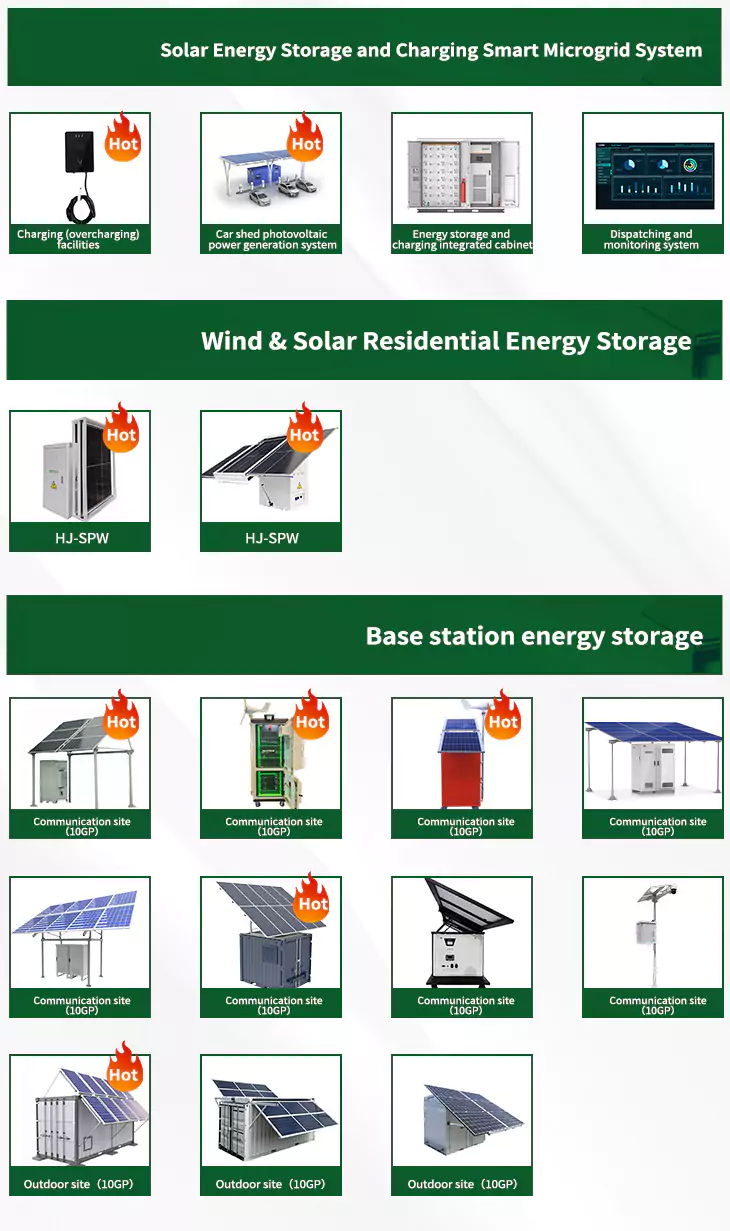

As the photovoltaic (PV) industry continues to evolve, advancements in Are photovoltaic panels nickel-plated have become critical to optimizing the utilization of renewable energy sources. From innovative battery technologies to intelligent energy management systems, these solutions are transforming the way we store and distribute solar-generated electricity.

When you're looking for the latest and most efficient Are photovoltaic panels nickel-plated for your PV project, our website offers a comprehensive selection of cutting-edge products designed to meet your specific requirements. Whether you're a renewable energy developer, utility company, or commercial enterprise looking to reduce your carbon footprint, we have the solutions to help you harness the full potential of solar energy.

By interacting with our online customer service, you'll gain a deep understanding of the various Are photovoltaic panels nickel-plated featured in our extensive catalog, such as high-efficiency storage batteries and intelligent energy management systems, and how they work together to provide a stable and reliable power supply for your PV projects.

6 FAQs about [Are photovoltaic panels nickel-plated ]

Is nickel/copper based metal plating a metallization method for silicon solar cells?

In recent times nickel/copper (Ni/Cu) based metal plating has emerged as a metallization method that may solve these issues. This paper offers a detailed review and understanding of a Ni/Cu based plating technique for silicon solar cells.

Are Ni/Cu plated solar cells better than screen printed solar cells?

Although the economic advantage of Ni/Cu plated solar cells against their screen printed counterparts is striking. Yet, the plating process needs to be optimized entirely, in terms of cost and performance. If just the material price is considered, the saving potential is relatively high.

Can Ni/Cu plating be used to metallize silicon solar cells?

The manufacturing costs of current silicon solar cells can be reduced by using inexpensive metals for metallization and thinner silicon substrates. This review has traced the prospective of Ni/Cu plating technique for metallization of silicon solar cells.

Can bifacial Topcon solar cells be plated?

coating (ARC) and plating of nickel, copper and silver can be successfully implemented in the fabrication sequence of bifacial TOPCon solar cells [7,8]. This work evaluates the implementation of plated TOPCon solar cells in PV modules and takes a closer look at the impact of cell breakage depending on the metalliza-tion type.

Can crystalline silicon solar cells be metallized using different plating approaches?

Conclusion In the present work, design rules to employ different plating approaches as metallization technology for different types of crystalline silicon solar cells have been discussed. After many years of experience, many of the formerly problematic phenomena can now be well controlled.

What are the disadvantages of metallization based photovoltaic technology?

Currently, contact formation using screen printing is the dominant technology in the silicon based photovoltaic industry, as it is simple and fast. However, metallization of this kind has the disadvantage in having a lower aspect ratio and higher contact resistance, limiting solar cell efficiency.

Related Contents

- Introduction to Ecological Photovoltaic Panels

- Photovoltaic panels blown over by wind

- Photovoltaic panels with better performance on cloudy days

- Rainwater gutters on photovoltaic panels

- Specifications and standards for horizontally mounted photovoltaic panels

- Calculation method of basic price of photovoltaic panels

- How do photovoltaic panels directly carry loads

- Deaf people installing photovoltaic panels

- Brief introduction to the invention of photovoltaic panels

- Comparison between photovoltaic panels and PC solar panels

- Photovoltaic panels with aging backsheet

- Photovoltaic panels without glass