About Thickness of photovoltaic bracket base

THE STANDARD IN PV MOUNTING STRUCTURES U.S. Des. Patent Nos. D496,248S, D496,249S. Other patents pending. SolarMount is much more than a product. It’s a system of engineered components that can be assembled into a wide variety of PV mounting structures. With SolarMount you’ll be able to solve virtually any PV module mounting challenge.

THE STANDARD IN PV MOUNTING STRUCTURES U.S. Des. Patent Nos. D496,248S, D496,249S. Other patents pending. SolarMount is much more than a product. It’s a system of engineered components that can be assembled into a wide variety of PV mounting structures. With SolarMount you’ll be able to solve virtually any PV module mounting challenge.

equivalent and must have the minimum thickness specified in Figure 7. Minimal material thickness is 3mm for the top and bottom sections, and 2mm for the vertical section, both with volume resistivity >.

The answer can be divided into two parts 2 solar laminate thickness and solar panel frame thickness. In 90% of situations, for 60-cell solar panels, the solar glass makes up the majority of the solar laminate thickness, measuring 3.2mm. Other parts include the solar cells, the solar laminate’s back sheet, and two encapsulant sheets.

Since my module thickness is 1.82", I use F type mid and end clamps, which are applicable for modules between 1.77" and 1.85". Please refer to the Unirac Master List, pages 6 to 8 or pages 20 to 22, to determine the size you will need to use.

This thickness significantly extends the life of the steel and can aid in fighting the effects of corrosive soils. Adding to this robust process is a scientifically optimized post design which offers maximum soil anchoring strength, surpassing I-beams or round poles. The module bearing portion of the FS System arrives partially pre-

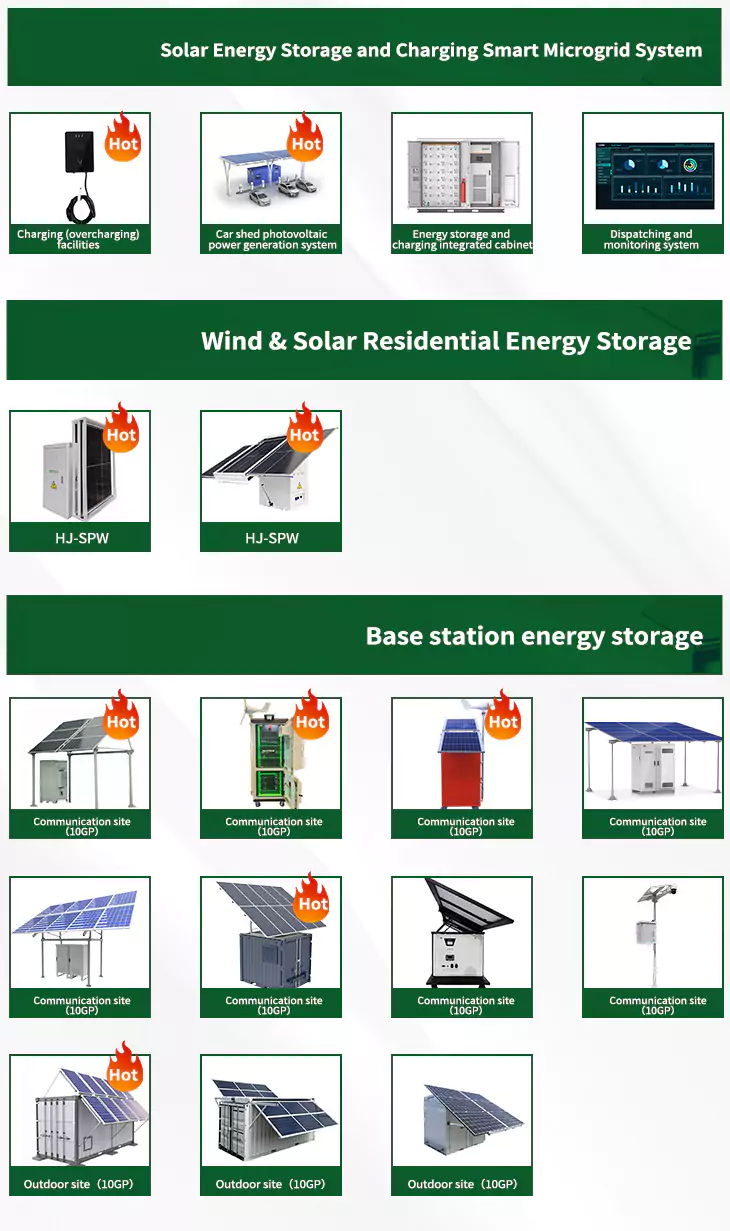

As the photovoltaic (PV) industry continues to evolve, advancements in Thickness of photovoltaic bracket base have become critical to optimizing the utilization of renewable energy sources. From innovative battery technologies to intelligent energy management systems, these solutions are transforming the way we store and distribute solar-generated electricity.

When you're looking for the latest and most efficient Thickness of photovoltaic bracket base for your PV project, our website offers a comprehensive selection of cutting-edge products designed to meet your specific requirements. Whether you're a renewable energy developer, utility company, or commercial enterprise looking to reduce your carbon footprint, we have the solutions to help you harness the full potential of solar energy.

By interacting with our online customer service, you'll gain a deep understanding of the various Thickness of photovoltaic bracket base featured in our extensive catalog, such as high-efficiency storage batteries and intelligent energy management systems, and how they work together to provide a stable and reliable power supply for your PV projects.

6 FAQs about [Thickness of photovoltaic bracket base]

What rack configurations are used in photovoltaic plants?

The most used rack configurations in photovoltaic plants are the 2 V × 12 configuration (2 vertically modules in each row and 12 modules per row) and the 3 V × 8 configuration (3 vertically consecutive modules in each row and 8 modules per row). Codes and standards have been used for the structural analysis of these rack configurations.

How do I choose a solar module mounting structure?

Ground Mounts: Perfect for bigger installations on open terrain. For maximum sun exposure, options include dual-axis trackers, single-axis trackers, and fixed-tilt mounts. Cost and Durability: Choose a solar module mounting structure that provides the most value for money while keeping durability, performance, and cost considerations in mind.

How to choose suitable locations for photovoltaic (P V) plants?

The selection of the most suitable locations for photovoltaic (P V) plants is a prior aim for the sector companies. Geographic information system (G I S) is a framework used for analysing the possibility of P V plants installation . With G I S tools the potential of solar power and the suitable locations for P V plants can be estimated.

Does a ground-mounted photovoltaic power plant have a fixed tilt angle?

A ground-mounted photovoltaic power plant comprises a large number of components such as: photovoltaic modules, mounting systems, inverters, power transformer. Therefore its optimization may have different approaches. In this paper, the mounting system with a fixed tilt angle has been studied.

What is the mounting structure of a P V module?

Choice of rack configuration of the mounting structure The mounting structure allows the P V modules to be securely attached to the ground with a fixed tilt angle. The mounting systems can be made of aluminium alloy, galvanized steel or stainless steel. Although, in large-scale P V plants the galvanized steel is generally used .

What affects the optimum tilt angle of a photovoltaic module?

(vi) The tilt angle that maximizes the total photovoltaic modules area has a great influence on the optimum tilt angle that maximizes the energy.

Related Contents

- Standard thickness of aluminum-magnesium-zinc photovoltaic bracket

- Is the thickness of the photovoltaic bracket 2 0 enough

- Photovoltaic aluminum alloy bracket wall thickness

- Photovoltaic bracket galvanized layer thickness gauge

- Photovoltaic bracket hot dip galvanizing anti-corrosion thickness

- Photovoltaic bracket aluminum material thickness standard

- Photovoltaic bracket base angle adjustment

- Photovoltaic bracket base plate accessories diagram

- Photovoltaic bracket base specification table

- Photovoltaic bracket waterproof base

- How to install the photovoltaic panel bracket base

- Photovoltaic panel base bracket installation drawing