About Generator blade mould manufacturer

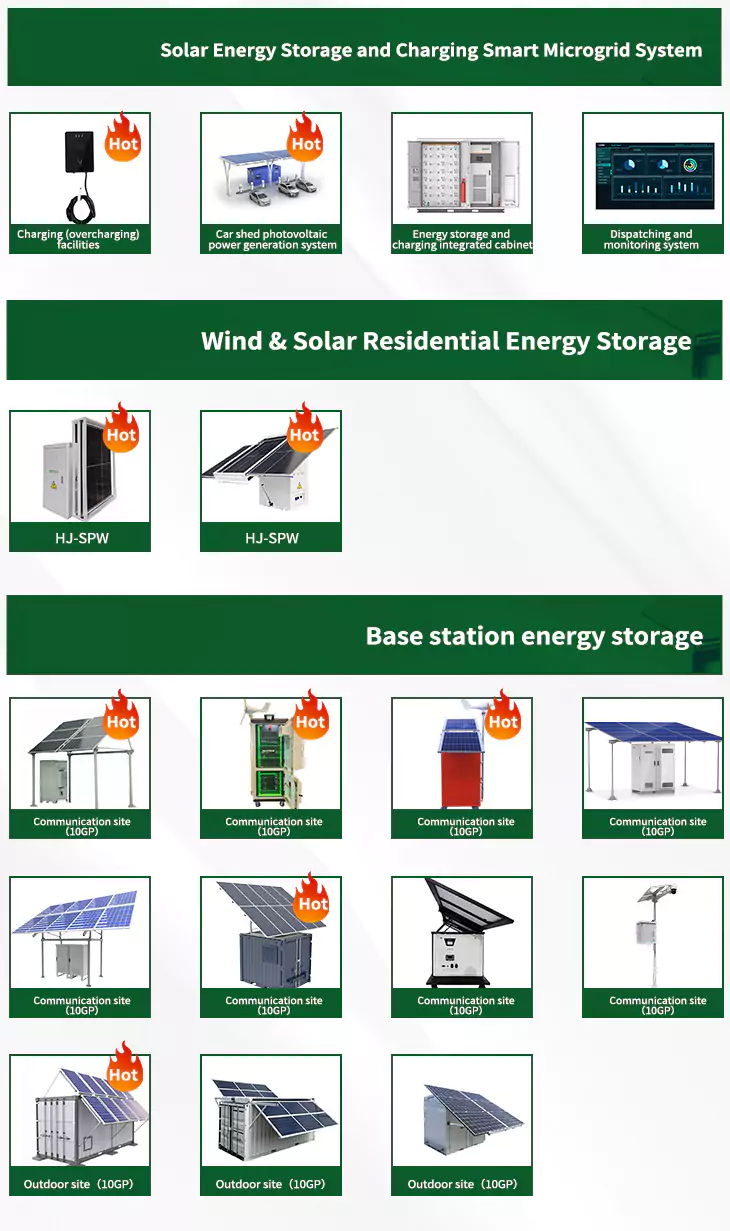

As the photovoltaic (PV) industry continues to evolve, advancements in Generator blade mould manufacturer have become critical to optimizing the utilization of renewable energy sources. From innovative battery technologies to intelligent energy management systems, these solutions are transforming the way we store and distribute solar-generated electricity.

When you're looking for the latest and most efficient Generator blade mould manufacturer for your PV project, our website offers a comprehensive selection of cutting-edge products designed to meet your specific requirements. Whether you're a renewable energy developer, utility company, or commercial enterprise looking to reduce your carbon footprint, we have the solutions to help you harness the full potential of solar energy.

By interacting with our online customer service, you'll gain a deep understanding of the various Generator blade mould manufacturer featured in our extensive catalog, such as high-efficiency storage batteries and intelligent energy management systems, and how they work together to provide a stable and reliable power supply for your PV projects.

6 FAQs about [Generator blade mould manufacturer]

Who makes wind turbine blade plugs & moulds?

Gurit is the largest independent manufacturer of plugs and moulds for wind turbine blades worldwide. Gurit offers a broad range of tools to precisely assemble prefabs onto a blade shell mould. We develop and offer complete Industry 4.0 solutions for your blade production fleet.

Who manufactures wind turbine blades?

Gurit is the largest independent manufacturer of plugs and moulds for wind turbine blades worldwide. Its dedicated Business Unit Manufacturing Solutions specializes mainly on wind turbine blade moulds and also blade production assisting equipment, including automated devices.

Can Gurit manufacture large scale mould sets?

Gurit has the ability to manufacture large scale mould sets. International blade manufacturers worldwide choose Gurit as their primary supplier for prototyping and serial mould production. You want to know more about Gurit's offering for the Wind Turbine Industry?

What are plugs & moulds?

Independent of the chosen composite manufacturing process, plugs – a three-dimensional model of final part – and moulds – the forms used to actually manufacture a final part – define the accuracy of composite components. Gurit is the largest independent manufacturer of plugs and moulds for wind turbine blades worldwide.

How many zones does a Wind Blade mould have?

The wind blade mould is normally divided up to 450 zones depending upon the blade structure design. Heating ramps of up to 2°C/min The patented liquid heating and cooling systems from Gurit are designed for further accuracy in the production cycle.

What is a gas turbine blade?

Gas turbine blades can be found in both compressor and turbine sections of gas turbines. Wind Turbine Blades: Wind turbine blades are designed to capture the kinetic energy of the wind and convert it into rotational motion. They are often large and made of lightweight materials to maximize efficiency.

Related Contents

- Generator blade manufacturer

- 150KW generator aluminum blade

- Wind blade generator blade size

- Working principle of shaft-type wind blade generator

- Wind blade generator maintenance

- Steam turbine generator blade materials

- 220v gasoline generator rotor blade removal method

- Generator blade shape

- Gasoline generator fan blade inspection standards

- Does the generator blade have residual value

- Wind blade generator installed on the mountain

- Spiral blade generator