About Photovoltaic silicone plate

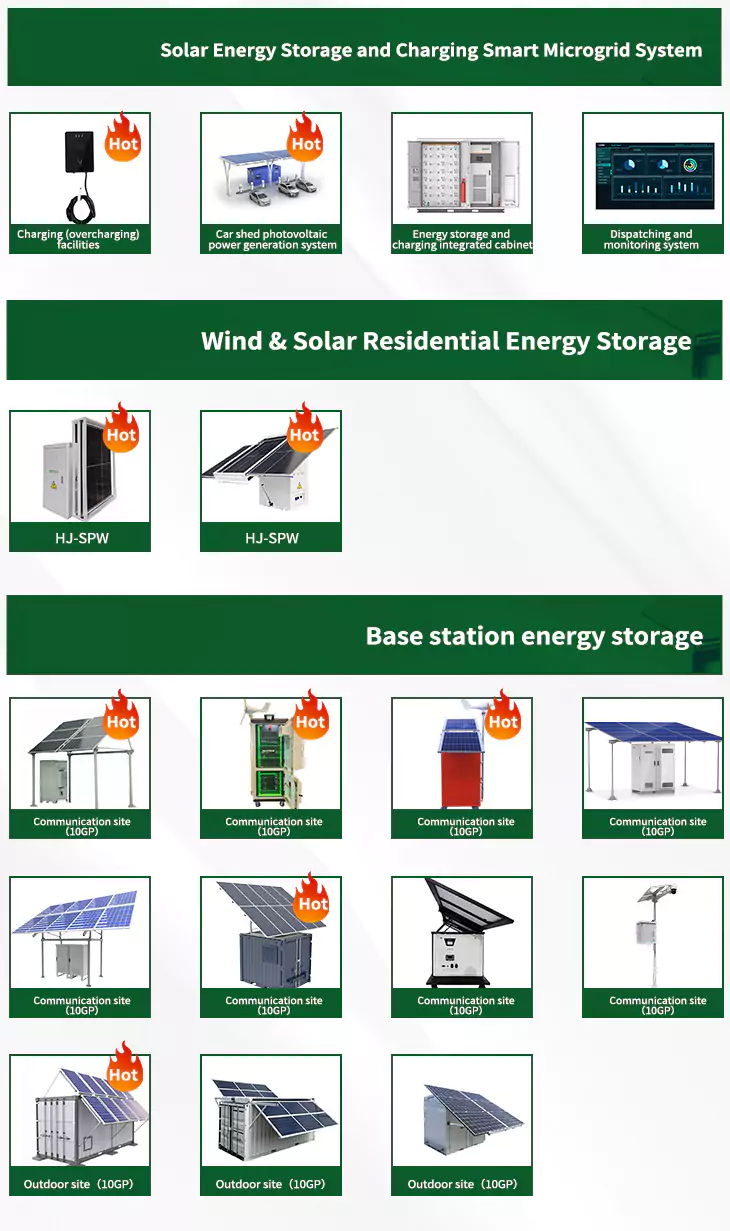

As the photovoltaic (PV) industry continues to evolve, advancements in Photovoltaic silicone plate have become critical to optimizing the utilization of renewable energy sources. From innovative battery technologies to intelligent energy management systems, these solutions are transforming the way we store and distribute solar-generated electricity.

When you're looking for the latest and most efficient Photovoltaic silicone plate for your PV project, our website offers a comprehensive selection of cutting-edge products designed to meet your specific requirements. Whether you're a renewable energy developer, utility company, or commercial enterprise looking to reduce your carbon footprint, we have the solutions to help you harness the full potential of solar energy.

By interacting with our online customer service, you'll gain a deep understanding of the various Photovoltaic silicone plate featured in our extensive catalog, such as high-efficiency storage batteries and intelligent energy management systems, and how they work together to provide a stable and reliable power supply for your PV projects.

6 FAQs about [Photovoltaic silicone plate]

Are crystalline silicon solar cells a good choice for photovoltaics?

The photovoltaics market has been dominated by crystalline silicon solar cells despite the high cost of the silicon wafers. Here Zou et al. develop a one-step electrodeposition process in molten salt to produce high-purity solar-grade silicon films, delivering power conversion efficiency of 3.1%.

Can thin-film silicon photovoltaics be used for solar energy?

The ability to engineer efficient silicon solar cells using a-Si:H layers was demonstrated in the early 1990s 113, 114. Many research laboratories with expertise in thin-film silicon photovoltaics joined the effort in the past 15 years, following the decline of this technology for large-scale energy production.

Can ultrathin silicon film be used for solar photovoltaics?

In a device design that brings mechanical flexibility to silicon photovoltaics, Jongseung Yoon, Alfred J. Baca and colleagues demonstrate how transfer-printing of ultrathin silicon films onto flexible substrates leads to semitransparent and large-scale arrays of integrated solar microcells with high solar-energy conversion efficiencies of 6–8%.

What are silicon-based solar photovoltaics cells?

Silicon-based solar photovoltaics cells are an important way to utilize solar energy. Diamond wire slicing technology is the main method for producing solar photovoltaics cell substrates.

What is crystalline silicon (c-Si) photovoltaics?

Provided by the Springer Nature SharedIt content-sharing initiative Crystalline silicon (c-Si) photovoltaics has long been considered energy intensive and costly. Over the past decades, spectacular improvements along the manufacturing chain have made c-Si a low-cost source of electricity that can no longer be ignored.

Will other PV technologies compete with silicon on the mass market?

To conclude, we discuss what it will take for other PV technologies to compete with silicon on the mass market. Crystalline silicon solar cells are today’s main photovoltaic technology, enabling the production of electricity with minimal carbon emissions and at an unprecedented low cost.

Related Contents

- Photovoltaic silicone plate equipment manufacturer

- Photovoltaic silicone plate

- How to install the photovoltaic panel fixing plate

- Is it good to use silicone in photovoltaic panels

- Photovoltaic maintenance channel grid plate supply

- Photovoltaic maintenance channel grid plate requirements

- Photovoltaic panel lower pressure plate diagram

- Photovoltaic panel U-bolt bending plate

- Ranking of photovoltaic pile end plate manufacturers

- Photovoltaic column top sealing plate

- Photovoltaic panels flow into the plate

- Photovoltaic operation and maintenance channel grid plate manufacturer