About Photovoltaic bracket adhesion test specification

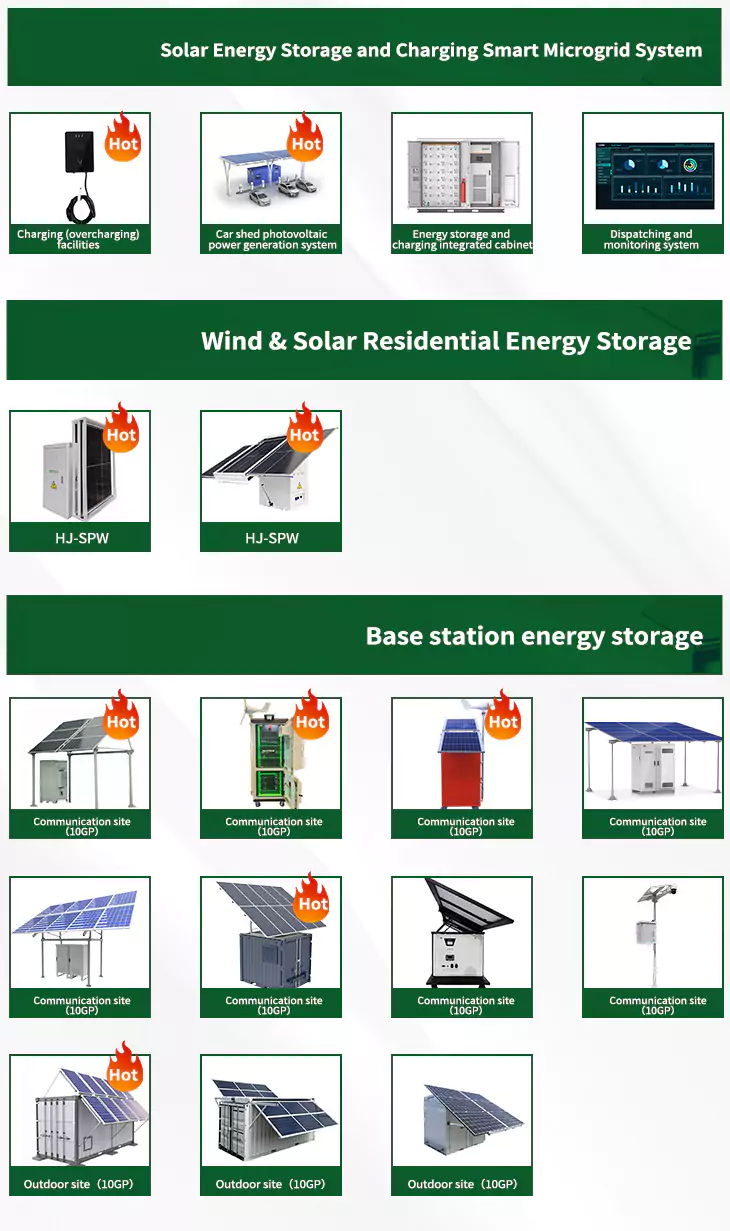

As the photovoltaic (PV) industry continues to evolve, advancements in Photovoltaic bracket adhesion test specification have become critical to optimizing the utilization of renewable energy sources. From innovative battery technologies to intelligent energy management systems, these solutions are transforming the way we store and distribute solar-generated electricity.

When you're looking for the latest and most efficient Photovoltaic bracket adhesion test specification for your PV project, our website offers a comprehensive selection of cutting-edge products designed to meet your specific requirements. Whether you're a renewable energy developer, utility company, or commercial enterprise looking to reduce your carbon footprint, we have the solutions to help you harness the full potential of solar energy.

By interacting with our online customer service, you'll gain a deep understanding of the various Photovoltaic bracket adhesion test specification featured in our extensive catalog, such as high-efficiency storage batteries and intelligent energy management systems, and how they work together to provide a stable and reliable power supply for your PV projects.

6 FAQs about [Photovoltaic bracket adhesion test specification]

Do photovoltaic modules have adhesion requirements?

Adhesion requirements for photovoltaic modules to ensure reliability are often discussed but not well defined, neither in terms of tests nor actual requirements. This paper presents a new approach for realistic assessment of the adhesion strength, which shows the conventional peel test may not ensure reliability.

How to determine adhesion strength?

adhesion strength is not easily defined. The requirements set today are for as produced modules. During normal operation, the values. Thus, tests should be conducted on the aged material. IV. D EVELOPMENT OF A NOV EL TEST would minimize additional testing effort. It also has the added

Why is a peel test necessary for a PV installation?

is the key to the financial success of any PV installation. PV erating environments in order to maintain long service life. De- the particular manufacturer. The pre valence of this failure mode cient to capture this issue. The peel test currently being used for November 1, 2017.

What are the dhesion requirements for PV modules?

A DHESION REQUIREMENTS FOR PV MODULES different layers is required for PV modules. For EV A encapsu- coupling agents added at the inner side of the backsheet. These creasing physical adsorption. The inner side of the backsheet is often another layer of EV A. This allows the molecules of sheet to EV A. The adhesion between EVA and glass (fge)is

Why are international standards important in the photovoltaic industry?

ABSTRACT: International standards play an important role in the Photovoltaic industry. Since PV is such a global industry it is critical that PV products be measured and qualified the same way everywhere in the world. IEC TC82 has developed and published a number of module and component measurement and qualification standards.

Can a peel test test the adhesion at a backsheet sublayer?

The peel test cannot test the adhesion at backsheet sublayers. ing weights (20 g/cm) as the second Y-axis. L140 sample did not fail after 1800 h exposure, which is plotted in the brackets. The time. Looking at the L125-P and L125-G result, the gravity test failed quickly. In contrast, the peel test w as performed at room of adhesion.

Related Contents

- Photovoltaic rainproof bracket specification parameter table

- Photovoltaic bracket base specification table

- Photovoltaic bracket cross-section size specification diagram

- Photovoltaic bracket pull-out force test table

- Specification requirements for photovoltaic panel excitation test

- Photovoltaic bracket drawing recognition specification

- Photovoltaic bracket bending specification requirements

- Photovoltaic panel bracket model specification table

- Photovoltaic bracket design specification books

- Photovoltaic panel bracket size specification table

- Photovoltaic panel high voltage test standard specification

- Photovoltaic bracket cross-section specification table