About Latest Specifications for Pile Foundation Distribution of Photovoltaic Panels

In the case of fixed photovoltaic plants, the metallic piles that are being used are cold-formed steel with a significantly lower edge, around 80-150 mm. In both cases, the width/length ratio of the foundation responds to a typology that could be classified as isolated short pile.

In the case of fixed photovoltaic plants, the metallic piles that are being used are cold-formed steel with a significantly lower edge, around 80-150 mm. In both cases, the width/length ratio of the foundation responds to a typology that could be classified as isolated short pile.

This paper presents a methodology for estimating the optimal distribution of photovoltaic modules with a fixed tilt angle in a photovoltaic plant using a packing algorithm (in Mathematica™ software) that maximizes the amount of energy absorbed by the photovoltaic plant.

As the demand for renewable energy increases—solar farms are becoming an ideal market for pile driving contractors due to the need for stable, long-lasting foundations that can support large-scale solar installations.

This case study focuses on the design of a ground mounted PV solar panel foundation using the engineering software program spMats. The selected solar panel is known as Top-of-Pole Mount (TPM).

The PHC (pre-stressed high-strength concrete) pile foundation, serving as an innovative supporting structure for solar power stations, is subjected to complex loading conditions in engineering scenarios. In this study, field tests of the full-scale PHC Pile foundation were conducted in sand layer, loess layer, and double-layer sites to .

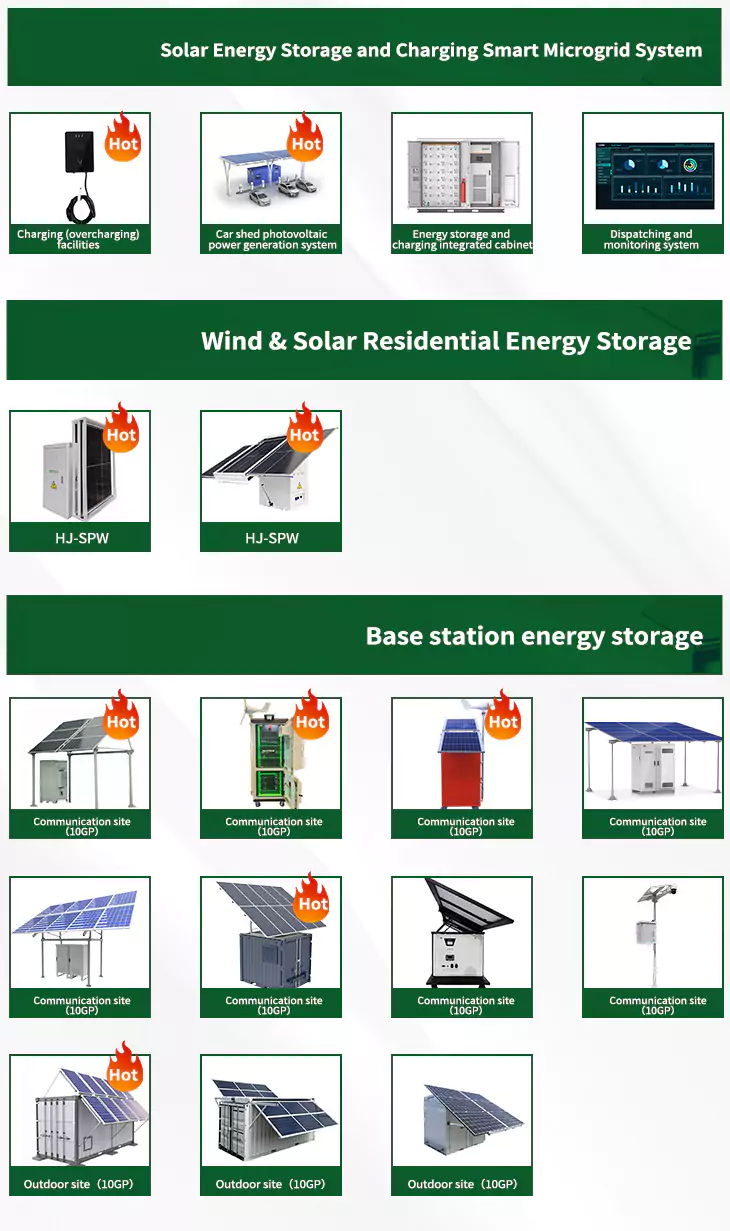

As the photovoltaic (PV) industry continues to evolve, advancements in Latest Specifications for Pile Foundation Distribution of Photovoltaic Panels have become critical to optimizing the utilization of renewable energy sources. From innovative battery technologies to intelligent energy management systems, these solutions are transforming the way we store and distribute solar-generated electricity.

When you're looking for the latest and most efficient Latest Specifications for Pile Foundation Distribution of Photovoltaic Panels for your PV project, our website offers a comprehensive selection of cutting-edge products designed to meet your specific requirements. Whether you're a renewable energy developer, utility company, or commercial enterprise looking to reduce your carbon footprint, we have the solutions to help you harness the full potential of solar energy.

By interacting with our online customer service, you'll gain a deep understanding of the various Latest Specifications for Pile Foundation Distribution of Photovoltaic Panels featured in our extensive catalog, such as high-efficiency storage batteries and intelligent energy management systems, and how they work together to provide a stable and reliable power supply for your PV projects.

6 FAQs about [Latest Specifications for Pile Foundation Distribution of Photovoltaic Panels]

What are the different types of photovoltaic support foundations?

The common forms of photovoltaic support foundations include concrete independent foundations, concrete strip foundations, concrete cast-in-place piles, prestressed high-strength concrete (PHC piles), steel piles and steel pipe screw piles. The first three are cast-in situ piles, and the last three are precast piles.

Can photovoltaic support steel pipe screw piles survive frost jacking?

To study the frost jacking performance of photovoltaic support steel pipe screw pile foundations in seasonally frozen soil areas at high latitudes and low altitudes and prevent excessive frost jacking displacement, this study determines the best geometric parameters of screw piles through in situ tests and simulation methods.

How is a ground mounted PV solar panel Foundation designed?

This case study focuses on the design of a ground mounted PV solar panel foundation using the engineering software program spMats. The selected solar panel is known as Top-of-Pole Mount (TPM), where it is deigned to install quickly and provide a secure mounting structure for PV modules on a single pole.

Is a PHC pile foundation a reliable support structure for heliostats?

A comprehensive design program is proposed based on field tests and numerical simulations, considering deformation and bearing capacity. The study confirms the reliability of the PHC pile foundation as a support structure for heliostats, aiming to offer valuable insights for practical applications.

What are the different types of foundations used in P V plants?

There are four types of foundations commonly utilized in large-scale P V plants. These types of foundations ordered from the lower to the higher cost-effective installation are : driven piles, earth-screws, helical piles and ballasted foundations. In this work, driven piles have been used. 3.8. Cost analysis

Are solar farms a good market for Pile Driving Contractors?

As the demand for renewable energy increases—solar farms are becoming an ideal market for pile driving contractors due to the need for stable, long-lasting foundations that can support large-scale solar installations.

Related Contents

- Latest photovoltaic panel pile position measurement specifications

- Latest specifications for photovoltaic panels

- The latest construction specifications for photovoltaic panels connected to the grid

- Concrete pile foundation construction of photovoltaic panels

- Can the pile foundation be installed with photovoltaic panels

- Photovoltaic panel pile foundation distribution diagram

- Latest news on planting blueberries with photovoltaic panels

- Latest price of photovoltaic panels in Vietnam

- Latest photovoltaic panel power supply installation specifications

- Latest specifications for photovoltaic panel testing standards

- The latest price list of photovoltaic panels in the park

- Latest specifications for photovoltaic panel slope installation