About Do photovoltaic inverter factories use lasers

To ensure photovoltaic systems are able to compete with conventional fossil fuels, production costs of PV modules must be reduced and the efficiency of solar cells increased. laser technology plays a key role in the economical industrial-scale production of high-quality solar cells.

To ensure photovoltaic systems are able to compete with conventional fossil fuels, production costs of PV modules must be reduced and the efficiency of solar cells increased. laser technology plays a key role in the economical industrial-scale production of high-quality solar cells.

Lasers lend themselves well to the needs of PV development such as drilling, trenching, ablation, welding and doping. Lasers may have been made for photovoltaics (PVs). Many of the materials used in PVs, such as silicon, metals and dielectrics, absorb laser light at the right wavelength; short-wave or pulsed lasers enable low optical and .

The manufacturing typically starts with float glass coated with a transparent conductive layer, onto which the photovoltaic absorber material is deposited in a process called close-spaced sublimation. Laser scribing is used to pattern cell strips and to form an interconnect pathway between adjacent cells.

Laser technology plays a key role in the economical industrial-scale production of high-quality solar cells. Fraunhofer ILT develops industrial laser processes and the requisite mechanical components for a cost-effective solar cell manufacturing process with high process efficiencies.

Potential remains high if at least one laser-based technique is adopted. The possibility that photovoltaic (PV) power conversion could cleanly, sustainably, and affordably power our homes and workplaces has captivated many for over half a century. Today, that vision is rapidly moving toward a reality.

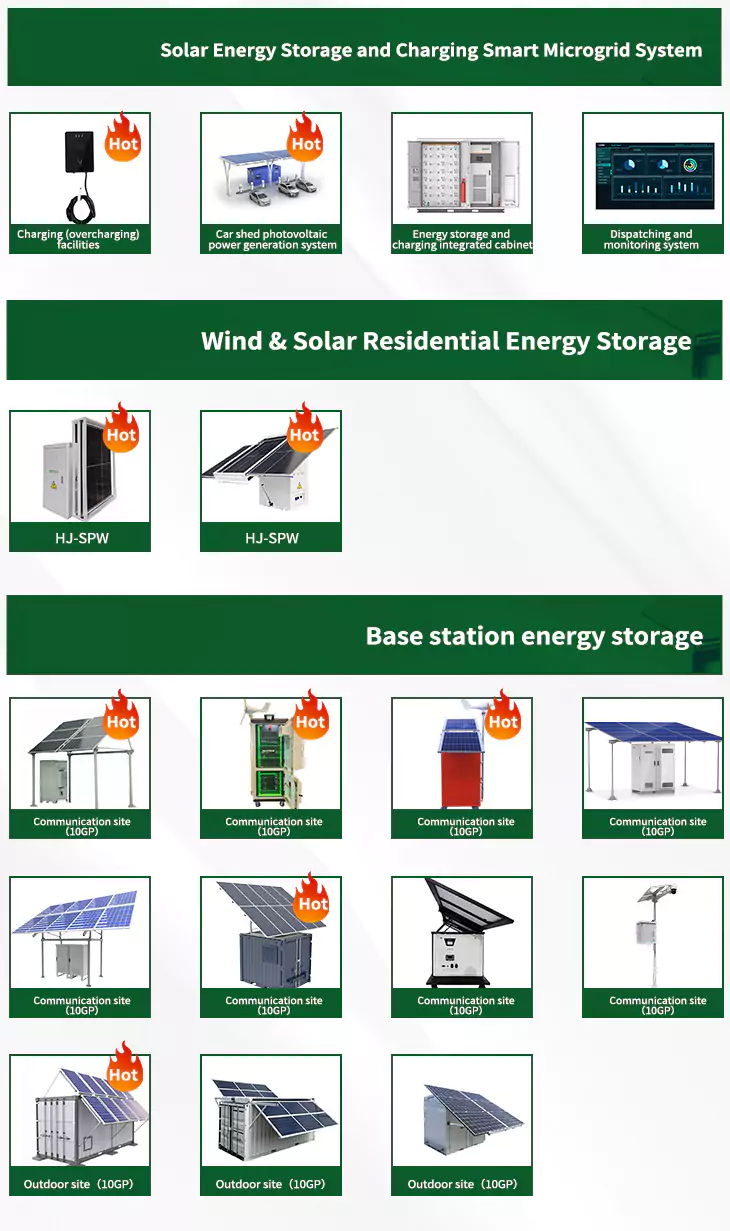

As the photovoltaic (PV) industry continues to evolve, advancements in Do photovoltaic inverter factories use lasers have become critical to optimizing the utilization of renewable energy sources. From innovative battery technologies to intelligent energy management systems, these solutions are transforming the way we store and distribute solar-generated electricity.

When you're looking for the latest and most efficient Do photovoltaic inverter factories use lasers for your PV project, our website offers a comprehensive selection of cutting-edge products designed to meet your specific requirements. Whether you're a renewable energy developer, utility company, or commercial enterprise looking to reduce your carbon footprint, we have the solutions to help you harness the full potential of solar energy.

By interacting with our online customer service, you'll gain a deep understanding of the various Do photovoltaic inverter factories use lasers featured in our extensive catalog, such as high-efficiency storage batteries and intelligent energy management systems, and how they work together to provide a stable and reliable power supply for your PV projects.

6 FAQs about [Do photovoltaic inverter factories use lasers ]

Why is laser technology important for solar energy production?

Solar energy is indispensable to tomorrow´s energy mix. To ensure photovoltaic systems are able to compete with conventional fossil fuels, production costs of PV modules must be reduced and the efficiency of solar cells increased. laser technology plays a key role in the economical industrial-scale production of high-quality solar cells.

How does laser technology affect the production of high-quality solar cells?

Laser technology plays a key role in the economical industrial-scale production of high-quality solar cells. Fraunhofer ILT develops industrial laser processes and the requisite mechanical components for a cost-effective solar cell manufacturing process with high process efficiencies.

Can laser processing systems be used for photovoltaic applications?

The laser processing systems for photovoltaic applications have advanced such that commercial systems are available. These commercial systems can provide multifunctional capabilities such that ohmic contact formation, dopant activation, and other steps that can be carried out using the same machine.

How are photovoltaic absorbers made?

The manufacturing typically starts with float glass coated with a transparent conductive layer, onto which the photovoltaic absorber material is deposited in a process called close-spaced sublimation. Laser scribing is used to pattern cell strips and to form an interconnect pathway between adjacent cells.

Can laser drilling be used for solar cell devices?

Laser drilling has also been used for solar cell devices, as shown in Fig. 19 (Gupta and Carlson 2015 ). Small holes allow the emitter current generated in the front of the cell to be transferred to the back of the cell for bus bar connections. Silicon solar cell device with laser formed buried contacts. (Reproduced from Bruton et al. 2003)

How does a laser work in a solar cell?

A laser from the Soliton / Advalue company is used. The wavelength of the laser beam is absorbed by the metal but not by the underlying silicon. As a result, the laser does not damage the silicon material in this process, which is advantageous for high solar cell efficiencies.

Related Contents

- How to use photovoltaic off-grid inverter

- How many watts of photovoltaic panels can a 10kw inverter use

- What communication method does the photovoltaic inverter use

- Does the photovoltaic inverter use mains electricity

- How many phases does the photovoltaic inverter use

- Does the photovoltaic inverter need to use mains electricity

- Photovoltaic grid-connected inverter off-grid use

- What inverter does Aobo Photovoltaic use

- How to use the photovoltaic inverter when power is off

- How to use the photovoltaic inverter safety lock

- How big an inverter should I use for a 10kw photovoltaic

- What inverter model should I use with 8kw photovoltaic panels